Improvement of formability of extruded aluminium profiles by a local short-term heat treatment

Third party funded individual grant

Start date :

01.10.2013

End date :

30.09.2020

Project details

Short description

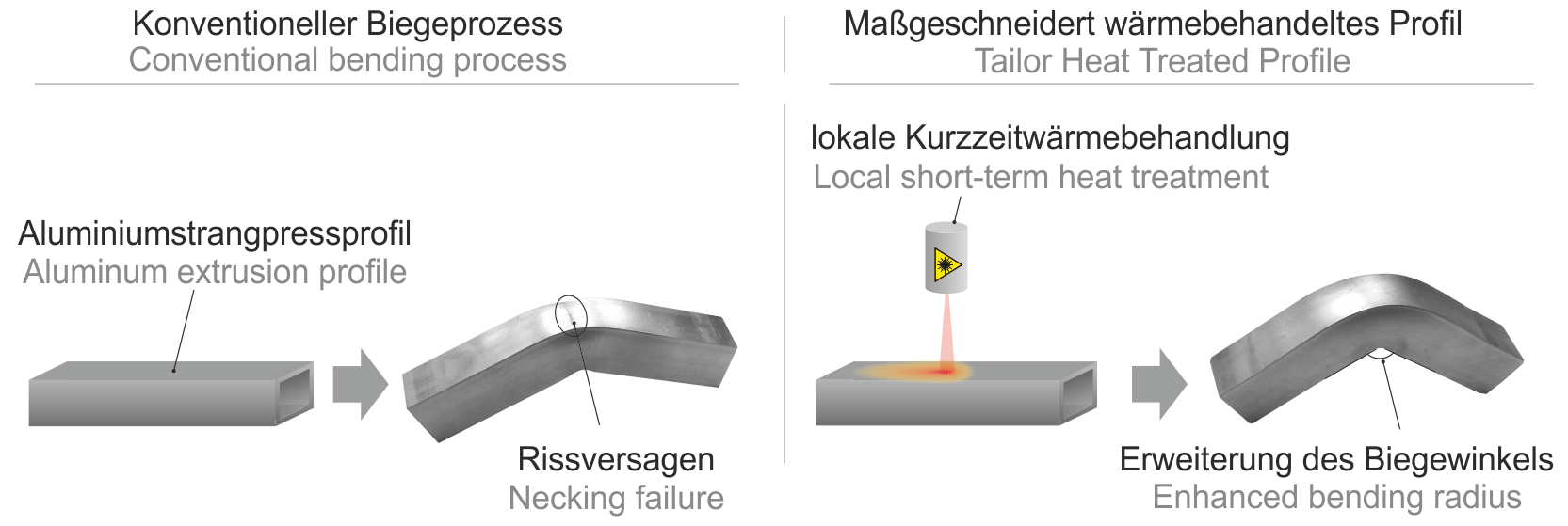

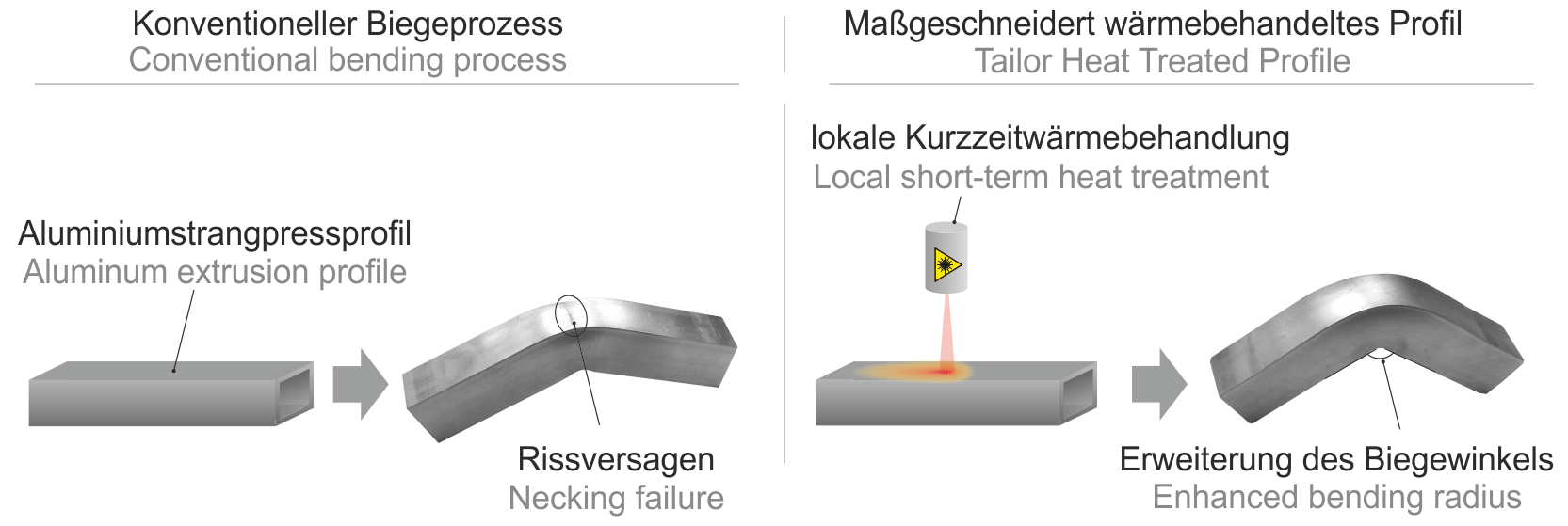

The objective of the

research project is the enhancement of the forming limits and the

tailoring of mechanical component properties of curved aluminum extruded

profiles by a local short-term heat treatment before the forming

process. Prerequisite for the successful application is the basic

scientific investigation of a short-term heat treatment of aluminum

extrusions and their interaction with a subsequent bending operation.

Based on the fundamental understanding and consideration of the complex

stress and strain state within profile bending an appropriate property

distribution is determined in order to improve the formality. A

suitable, laser-assisted heat treatment should be derived using a heat

treatment simulation, which predicts the new mechanical properties in

dependency of the microstructural changes. Finally, the artificial

ageing capability of the material will be investigated.

Scientific Abstract

Aim of the research project is the enhancement of the forming limit and the adjustment of the final mechanical properties of curved aluminum profiles by tailored heat treatment before the forming process. The influence of a short term heat treatment on aluminium profiles and the interaction with subsequent bending operation will be investigated fundamentally. This is a significant enhancement of the state of the art. Until now, in particular, fast hardenable aluminum blank alloys, which were especially developed for a short term heat treatment, were analyzed. The influence of a short term heat treatment on the mechanical properties of extruded aluminum profiles is not investigated yet. Regarding the influence on the microstructure there is only basic knowledge. On the one hand it is to be analyzed what microstructure and property changes can be induced due to the thermal treatment and how they can be controlled by a heat treatment process. Based on the basic understanding an appropriate property distribution should be determined in order to extend the forming limit, taking into account the complex stress and strain state in profile bending. Criteria for the improvement will be the contour accuracy achieved during the forming process or the reduction of the bending radius for the same cross-sectional deformation. The heat treatment will be designed using a thermo-mechanically coupled simulation which can determine the change of the mechanical properties derived by microstructural dissolution of precipitations. Finally, the question arises, how the interaction of a heat treatment and a bending operations affect the subsequent aging mechanisms and which final properties at the end of the process chain can be realized.

Contributing FAU Organisations:

Funding Source