Contribution to an efficient FE-based design of magnesium sheet parts

Third party funded individual grant

Start date :

01.10.2014

End date :

30.06.2017

Project details

Short description

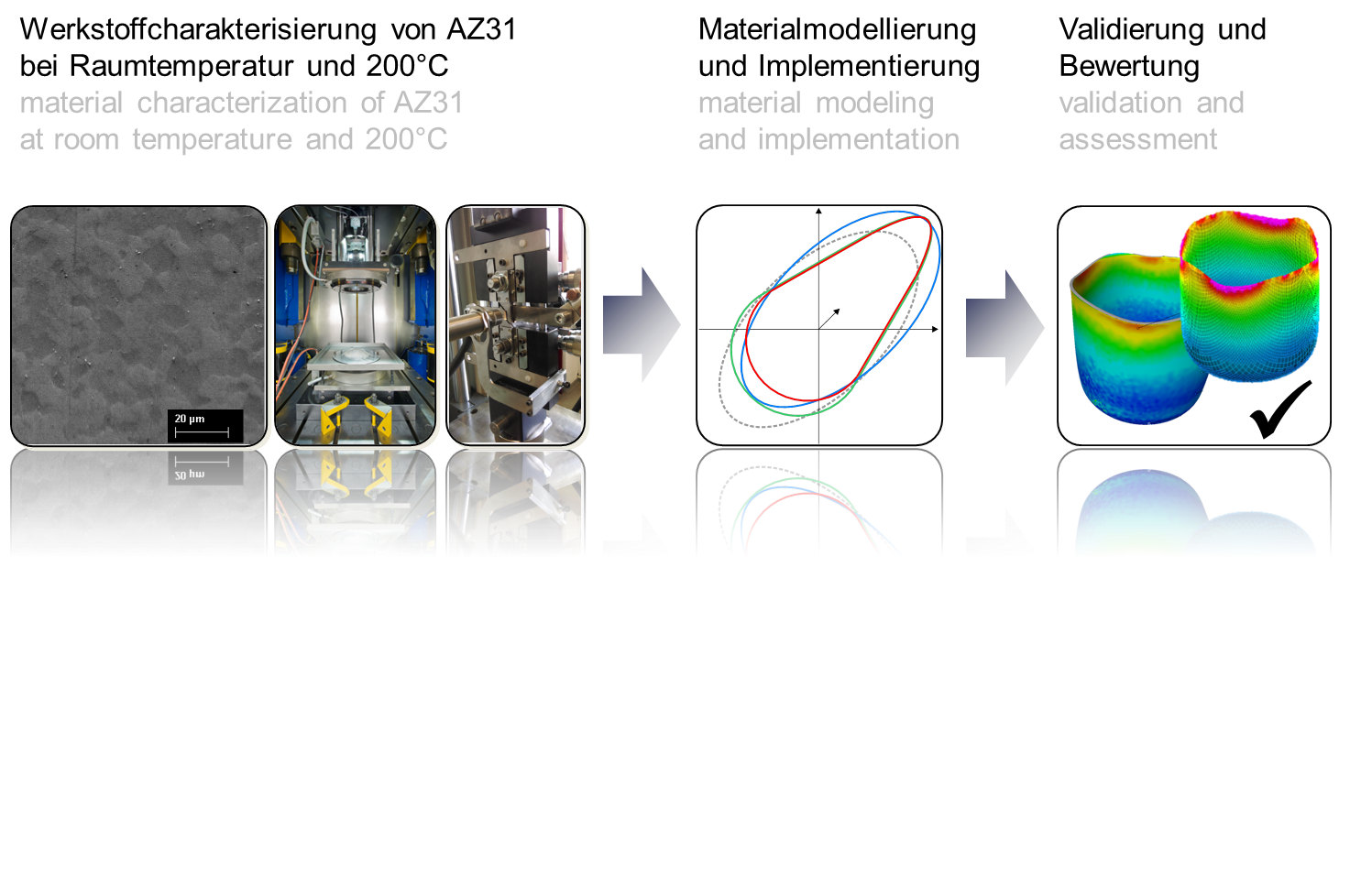

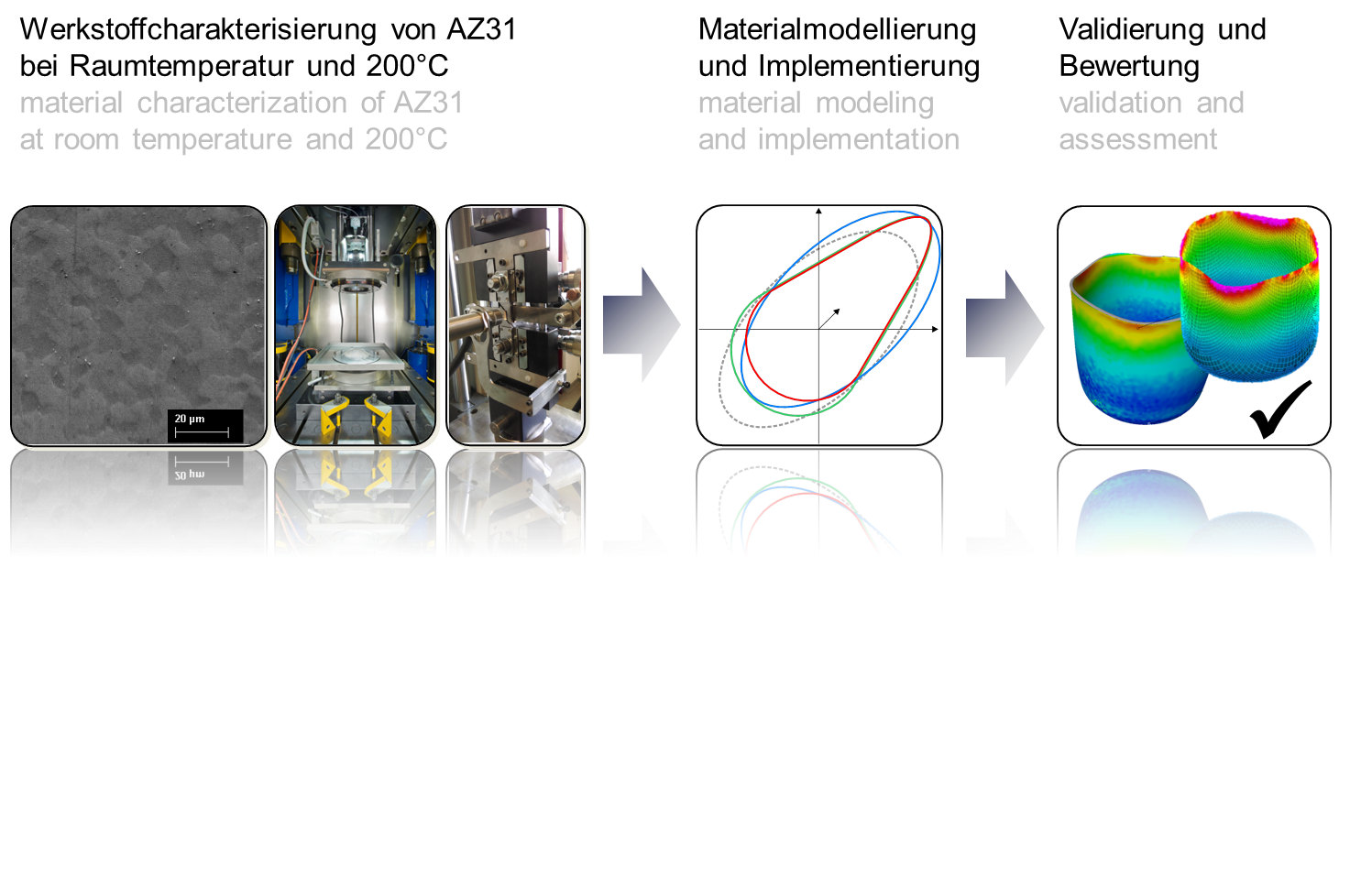

This fundamental research project funded

by the German Research Foundation (DFG) comprises the numerical

analysis of the plastic material behavior of magnesium alloys with the

help of implementation, enhancement and experimental validation of an

efficient constitutive model.

Thus, the numerical design and analysis

of magnesium sheet metal parts from the magnesium alloy AZ31 is

significantly improved. Fundament of this project is the use and

enhancement of existing test methods for the characterization of

magnesium alloys at room temperature and elevated temperatures developed

at LFT. An exact parameter identification for a fundamental

understanding of the complex material behavior of magnesium alloys is

used to the calibration of an isothermal numerical model at room

temperature and at 200 °C. The characteristic of the material behavior,

the anisotropic behavior and the tension-compression-asymmetry, is

considered with the identification of a complex material model for the

numerical simulation.

The evaluation of the identified

plasticity model's efficiency results from the validation of the

numerical model on an experimentally drawn demonstrator part.

Scientific Abstract

Light weight construction is for automotive manufactures a known strategy in order to reduce car´s weight, fuel consumption and overall greenhouse emissions. In order to meet these targets the use of aluminum alloy as well as higher- and high-strength steels has increasingly become a standard for series production. Magnesium has struggled for acceptance despite the low density, mainly due to the lack of knowledge of its unusual plastic behavior and the absence of adequate material models in commercial FE-programs. The mission of the present research project is to implement and further develop an efficient material model for magnesium sheets in order to overcome this deficit. For this purpose, the constitutive material model called TWINLAW from Li et al. (2010) will be implemented in ABAQUS/Standard using a UMAT subroutine. The von Mises yield criterion of the model in its original form will be substitute by an advanced anisotropic yield criterion to address the pronounced anisotropy of the material. The implementation of the only partially described model together with its further development represents a challenging task. In fact, the whole constitutive model will be impacted by the adoption of an advanced anisotropic yield criterion and will likely undergo a major rework. It is among other things expected that the integration algorithm will be changed because of the complexity of the new flow surface. Supplementary to Li et al. (2010) whose investigations were carried out at room temperature only, the model will be isothermally tested at enhanced temperatures. This validation in a relevant forming technology temperature range will be performed using already implemented as well as new experimental methods.

Contributing FAU Organisations:

Funding Source