Improvement of the application characteristics of multi-layered sheet material for forming technology produced via Accumulative Roll Bonding

Third party funded individual grant

Start date : 01.01.2018

End date : 31.12.2019

Extension date: 15.09.2021

Project details

Short description

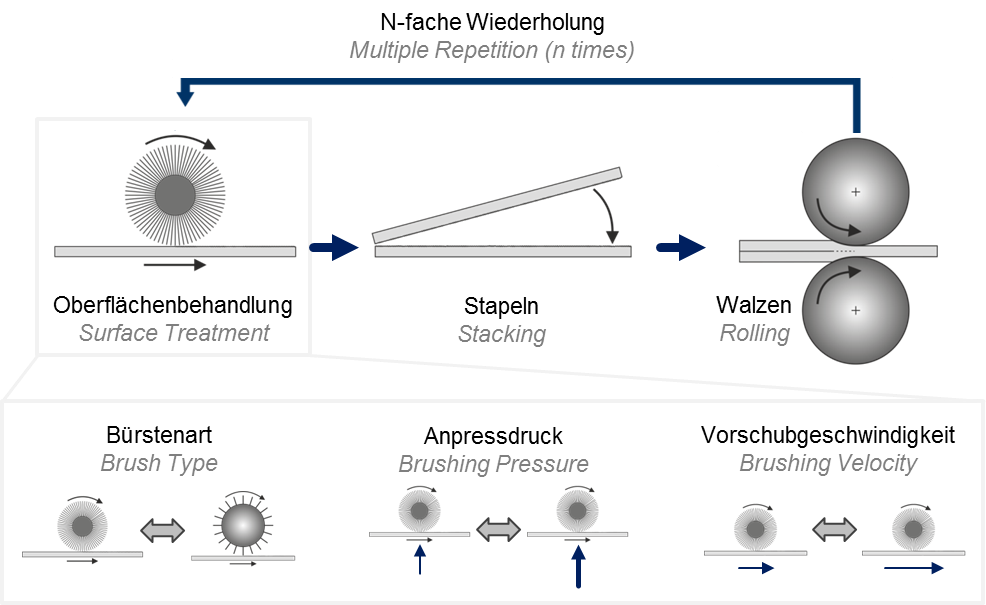

The Accumulative Roll Bonding process enables the production of multilayered and high-strength sheet products. Repeated rolling produces an ultrafine-grained microstructure, which leads to a significant increase in strength while maintaining a good ductility. A high bond strength between the layers hinders delamination processes and is strongly dependent on the surface treatment of the bonded interfaces. In order to improve the process reliability, it is implemented with the aid of a robot assisted brushing unit. The scientific objective is to identify a surface treatment process window which is advantageous for the formability of multilayered sheets. Based on the present analyses, it can be concluded that a homogeneous brushing treatment is essential for good bonding and thus forming properties.

Scientific Abstract

The Accumulative Roll Bonding process enables the production of multilayered and high-strength sheet products. Repeated rolling produces an ultrafine-grained microstructure, which leads to a significant increase in strength while maintaining a good ductility. A high bond strength between the layers hinders delamination processes and is strongly dependent on the surface treatment of the bonded interfaces. In order to improve the process reliability, it is implemented with the aid of a robot assisted brushing unit. The scientific objective is to identify a surface treatment process window which is advantageous for the formability of multilayered sheets. Based on the present analyses, it can be concluded that a homogeneous brushing treatment is essential for good bonding and thus forming properties.