Laser implantation of press hardening tools to influence the tribological and thermal properties for the process application (DFG ME 2043/68-1)

Third party funded individual grant

Start date : 01.07.2018

End date : 30.06.2020

Extension date: 31.08.2020

Project details

Short description

Key development goals of the automotive industry are to increase the passenger safety as well as to reduce the fuel consumption and to observe emission regulations. The lightweight concept of body-in-white parts enables the realization of these goals and sets new standards in terms of functionality and aesthetics. Hence, hot stamping has been established as a suitable and resource efficient process to manufacture high-strength components.

This method combines the hot forming and quenching of semi-finished parts in one process step. The high ultimate tensile strength of the components is caused by a transformation of an austenitic into a martensite structure. Due to the high process temperatures the hot stamping tools are exposed to high thermo-mechanical stresses. In addition, the workpiece out of 22MnB5 is coated with an AlSi layer to protect the surface against oxidation and decarburization. As a side effect, this coating system leads to an increased adhesive wear on the tool surface. A time and cost consuming rework of the hot stamping tool is required. The use of lubricant is not possible at elevated temperatures.

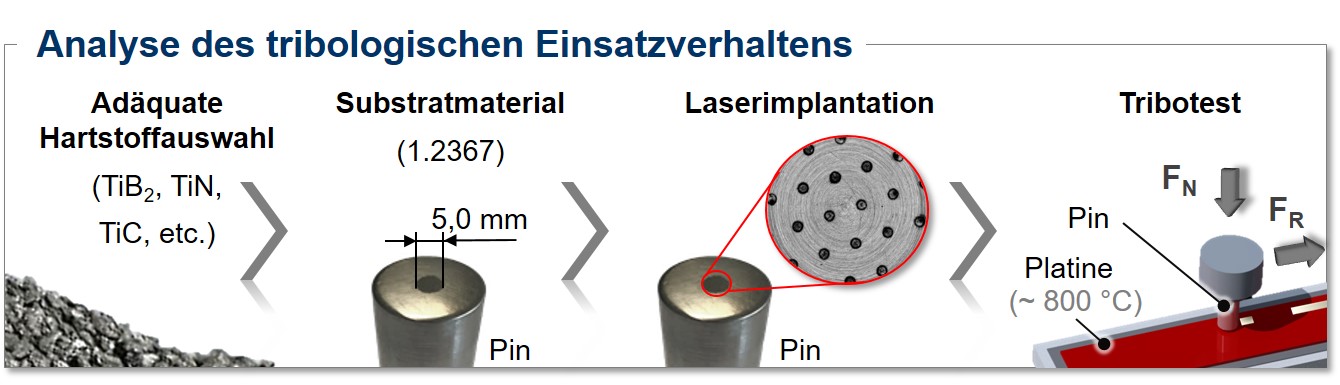

The overall aim of this research project is to increase the wear resistance of hot stamping tools. Therefore a laser implantation process is realized in cooperation with the Federal Institute for Materials Research and Testing. In highly stressed areas ceramic hard materials are dispersed into the substrate material in deterministic patterns using a pulsed laser beam. The wear, friction and cooling behavior of the modified tool surfaces are analyzed before and after the tribological stress. With this knowledge specific guidelines for industrial applications can be deduced.

Scientific Abstract

Key development goals of the automotive industry are to increase the passenger safety as well as to reduce the fuel consumption and to observe emission regulations. The lightweight concept of body-in-white parts enables the realization of these goals and sets new standards in terms of functionality and aesthetics. Hence, hot stamping has been established as a suitable and resource efficient process to manufacture high-strength components.

This method combines the hot forming and quenching of semi-finished parts in one process step. The high ultimate tensile strength of the components is caused by a transformation of an austenitic into a martensite structure. Due to the high process temperatures the hot stamping tools are exposed to high thermo-mechanical stresses. In addition, the workpiece out of 22MnB5 is coated with an AlSi layer to protect the surface against oxidation and decarburization. As a side effect, this coating system leads to an increased adhesive wear on the tool surface. A time and cost consuming rework of the hot stamping tool is required. The use of lubricant is not possible at elevated temperatures.

The overall aim of this research project is to increase the wear resistance of hot stamping tools. Therefore a laser implantation process is realized in cooperation with the Federal Institute for Materials Research and Testing. In highly stressed areas ceramic hard materials are dispersed into the substrate material in deterministic patterns using a pulsed laser beam. The wear, friction and cooling behavior of the modified tool surfaces are analyzed before and after the tribological stress. With this knowledge specific guidelines for industrial applications can be deduced.