Foam simulation

Description / Outline

The foam simulation focuses on the modelling and implementation of the physical phenomena during foam formation of metallic as well as polymeric materials. The aim is to predict improved process strategies of foam formation.

Metal Foams:

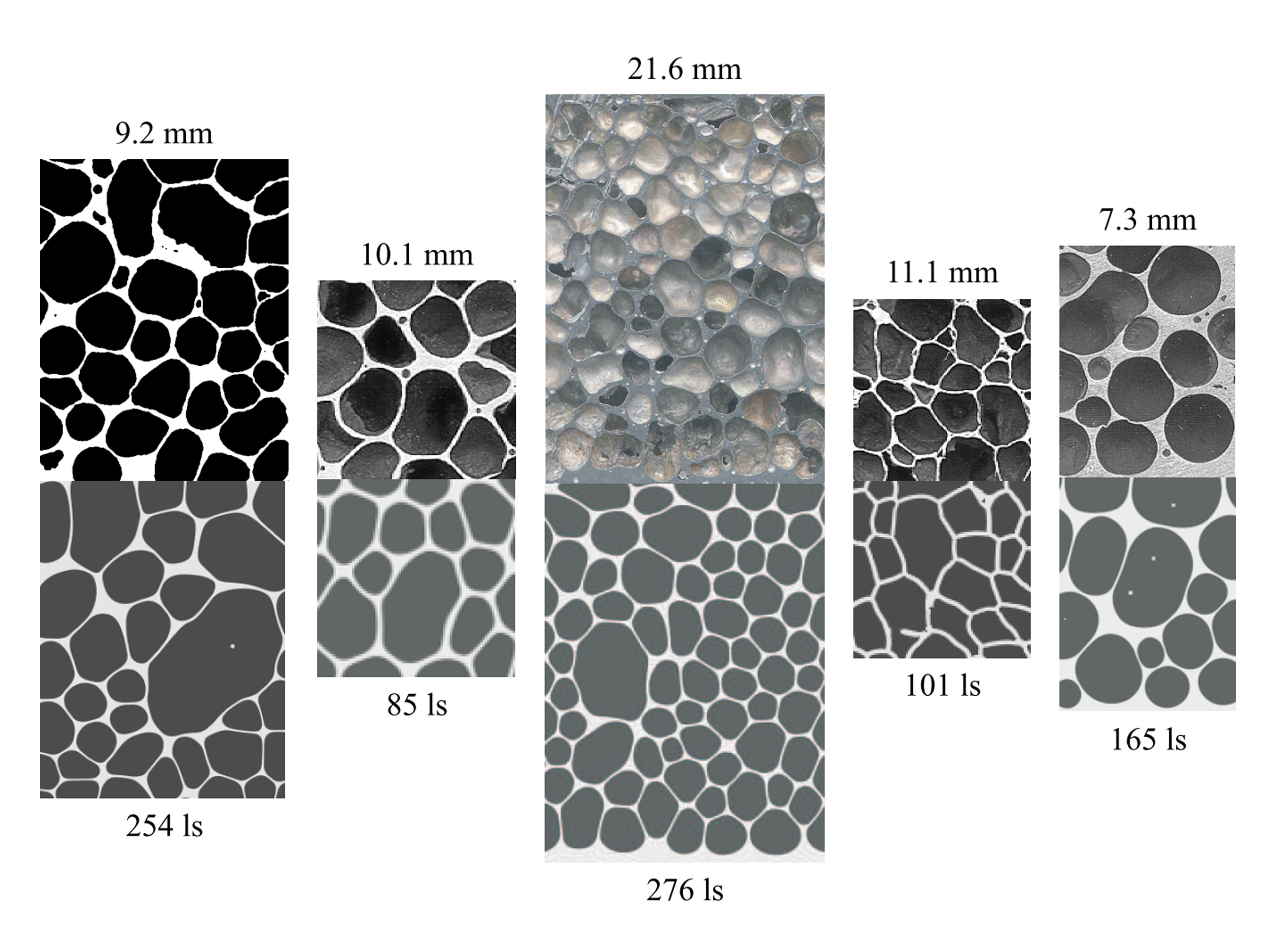

Until today, metallic foams are not common despite their potential for energy absorption and ultra-light components. The main disadvantage are the inhomogenities of the pore structure, which includes variations in the pore size, geometry and wall size. The aim is to understand the underlying effects during foam formation to improve the process.

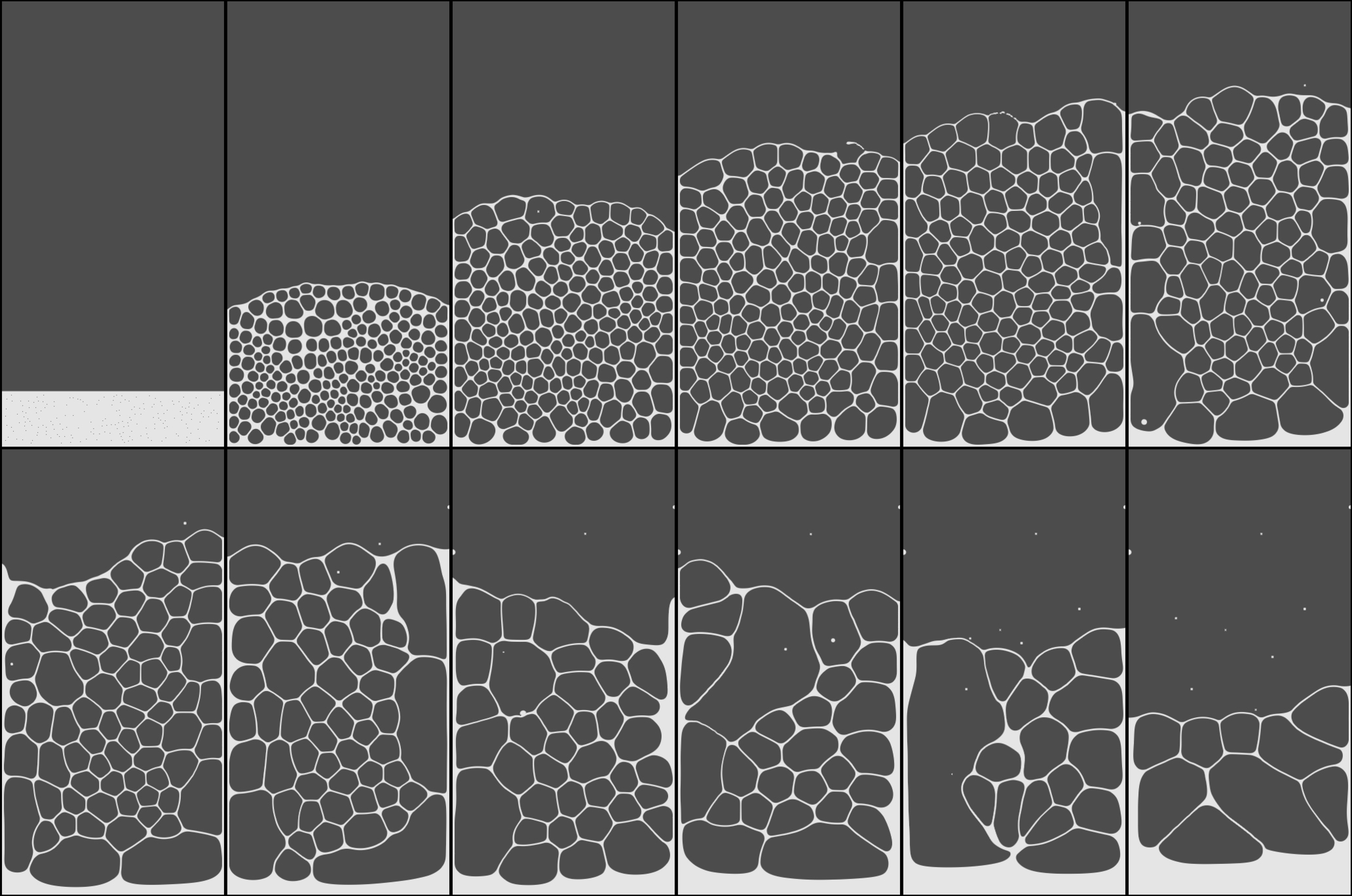

The implemented software bases on the lattice Boltzmann method, covers he most important physical effects during foam formation and is able to predict modified process strategies. The implementation comprises the hydrodynamic, diffusive and thermodynamic conservation equations applied on free surfaces. The physical models cover the growth, coarsening, reordering and collapse of foam bubbles as well as effects of the whole pore network like aging and drainage due to capillarity and wetting.

Viscoelastic Foams:

Foam materials are due to their cellular structure an interesting material class with attractive properties. The software used for metal foams was extended to simulate the viscoelastic effects during foaming of polymers. Therefore, the numerical method was extended by a rheological model for viscoelastic fluids applied on free surfaces. With this software, the influence of different process parameters on the foam formation was studied.